I've wanting to build heated chamber from last year, since I installed dual extruder and heated bed mod for printing ABS and PLA dissolvable support. Dissolvable support is crucial for outputting quality prints on par with commercial FDM machines which handle massive overhangs relatively well.

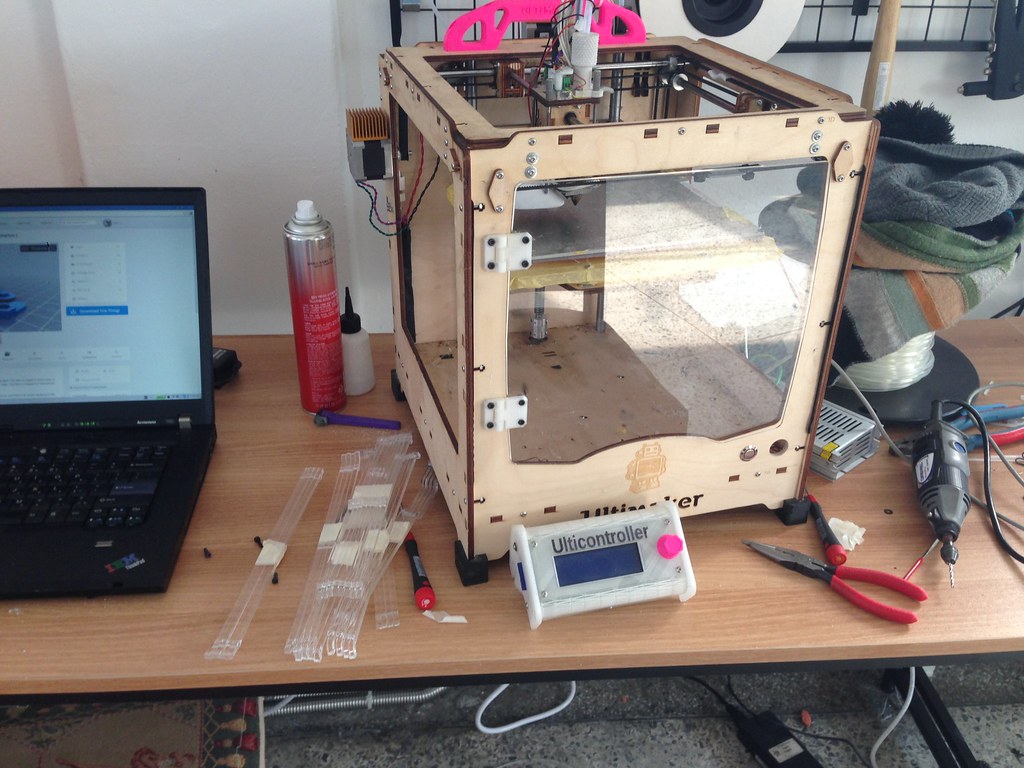

[caption id="" align="alignnone" width="819"]

Laser cut and stacked.[/caption]

Laser cut and stacked.[/caption]X-Y steppers are already moved to the outside and they stay cool. Stacked set-offs fit well. The only problem is acrylic sheets vary in thickness from point to point even within a single sheet. I used 5mm acrylic sheet for set offs but the thickness differ around 5% so I used washers to compensate the distance and reduce tensions caused by nearby tightened nearby bolts. I drilled several holes on the chassis to mount everything. Hinges were also printed.

Top cover has opening and lock(black part) for cables to stay in place. I used flexible PLA for flaps, which prevent heat from escaping.

With 120W power supply it heats up to 70"C in 8-9 minutes in winter. It started from fairly cold temperature(12'C) so in most cases it should be around 7. But it still takes longer than 30 minutes to reach over 90"C, it requires larger power supply but I think I will keep it this way since current power supply is pretty slim and fits nicely underside, makes it invisible.

All drawings are posted here

http://www.youtube.com/watch?v=rkOUlJ2kweQ

[…] http://minifacture.wordpress.com/2014/03/07/ultimaker-heated-chamber/ […]

ReplyDelete